Today we are going to talk about the bursting of the spline of the China-made Sauer Danfoss 90R130 replacement cylinder blocks. A brand new cylinder block, the customer received it and installed the replacement barrel within less than 2 weeks. Any of the hydraulic maintenance engineers who encounter this kind of quality problem will definitely be extremely angry and disappointed with the cylinder block made in China.

1), Reasons why such problem happened there?

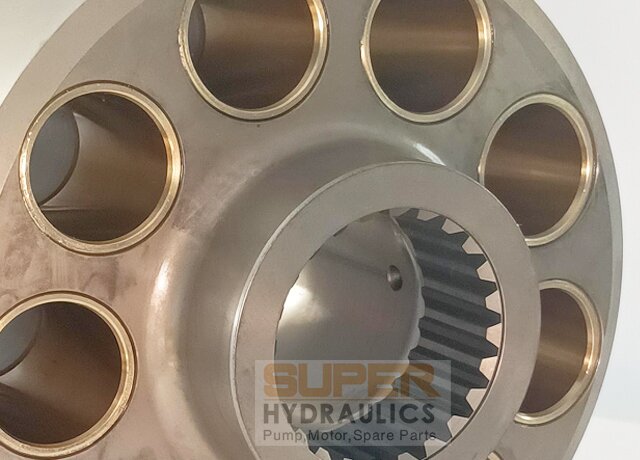

The most fundamental reason for bursting is that the spline part is too brittle and the cylinder block material has insufficient toughness. When the Hydraulic Pump is running at high power, the strong rotational torque directly breaks the brittle splines. After analysis, the spline part of this burst replacement 90R130 cylinder block adopts a "high-frequency quenching heat treatment process" (the spline surface that needs to be hardened is quenched to a depth of 0.5mm to 0.8mm to reach a hardness around HRC40~HRC50, the black part is quenched showed as below picture, and the silver part is without quenching treatment.

To be honest, this heat treatment process is the same as the OEM 90R130 cylinder block. But why are cylinders made in China prone to bursting, but not the OEM ones?

We believe that the main difference is that the material quality of the original cylinder is better than that of Chinese materials, and also the original "high-frequency quenching heat treatment process" is more advanced and uniform. The Chinese heat treatment process is not up to par, causing the whole spline part to be easily heated, quenched, and hardened as a whole. The brittleness is too high, and the spline part is too fragile and then result in bursts.

This high-frequency quenching heat treatment process is more common in hydraulic pump cylinders made in China. It has low cost and high efficiency. As mentioned in the article, the possibility of cylinder bursting is also high. The advantage is that the product price is low!

2), What improvements have Super Hydraulics' cylinder blocks made to prevent possible bursts? Will also burst?

In response to the above quality problems, all cylinder blocks we are currently sourcing and selling adopt the "overall nitriding process" and do not use "high-frequency quenching heat treatment process". The nitriding heat treatment process will strengthen the surface hardness of the splines to HRC55~HRC60, and the nitriding layer depth is only between 0.2mm and 0.35mm. The hardness of the steel base below the nitrided layer is only between HRC25 and HRC28. The material has high toughness and is sufficient to handle the powerful rotational torque brought by the motor under high power and high impact conditions. This kind of integrally nitrided cylinder block has high manufacturing cost and low efficiency, resulting in a higher parts price.

Over 20 years of experience in Hydraulics and as a leading manufacturer for quality replacement hydraulic components and parts in China, we know hydraulics better and know how to control the quality and supply all our customer with the best quality and much competitive hydraulics products made in China. All hydraulic cylinder blocks of bi-metal sold by Super hydraulic are all strictly quality checked, only with "overall nitriding process" to guarantee a high quality. The poor cylinder blocks with "high-frequency quenching heat treatment process" will never be supplied by Super Hydraulics. But, you have more than 80% possibility to get such poor cylinder blocks from other China hydraulic suppliers.

Kindly work with Super hydraulics and make Super be your reliable, valuable, one-stop hydraulics partner in China.

Super Hydraulics, Make The Difference!

Contact: Frank Xie

Phone: +86-18951952293

Tel: +86-25-83408096

Email: sales@super-hyd.com

Add: 97#, Luxiying, Gulou Dis, Nanjing, China.

We chat