A hydraulic piston pump is composed of many parts, forming dozens of friction pairs, we often say that the three major friction pairs of the piston pump refer to:

1), The sliding shoe pair formed between the piston shoe and the swash plate.

2). The oil distribution pair composed of the cylinder block and the port plate.

3). The piston pair composed of the piston rod and the cylinder hole.

The above hydraulic oil film lubrication characteristics of these three pairs of friction pairs determine the service life of a piston pump.

Following we are going to talk about one of the most critical friction pairs in the swash plate variable piston pump A4VG250: "The sliding shoe pair formed between the piston shoe and the swash plate".

Some of our customers complained that they had purchased some A4VG250 plungers from other manufacturers in China, and in the low pressure state, it seemed that the quality was okay, and there was no big quality problem. However, once the pressure rises to 25MPa or higher, the piston shoe is easy to be worn and damaged.

The static pressure friction surface of a piston shoe should take into account the pump from stationary to starting state, the process state of the number of revolutions from low elevation, the long-term low-pressure standby state, the piston rod suction at high pressure, the alternating process of the conversion pressure field during the oil discharge process, the micro-deformation control of the sliding shoe after the single peak pressure exceeds 10 seconds, and the stress state of the piston shoe after the instantaneous ultra-high pressure impact.

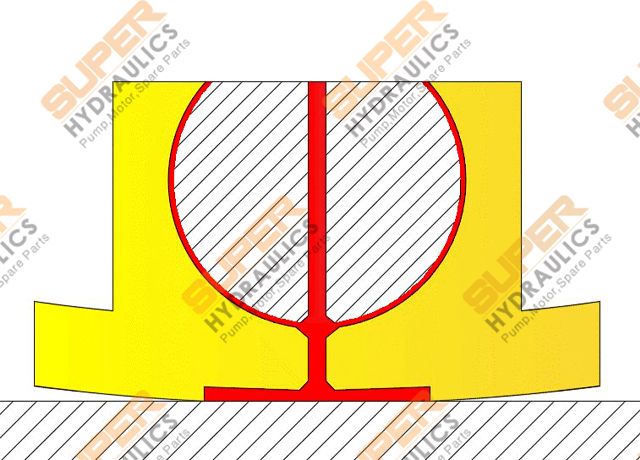

In the high-pressure state, the surface of the copper sliding shoe will be subjected to a great force to press the swash plate, if the ductility of the copper is not very good, in the high-pressure state, the sliding shoe will produce serious deformation, as shown in the figure. When the pressure drops, the copper material will be deformed back to its original shape. This happens quite often.

Some China piston pump manufacturers, the use of conventional copper, can not ensure sufficient elongation, know it but do not know why, according to the cat and the tiger, the manufacture of the piston pump in the pressure reaches high pressure, the copper piston shoe plastic deformation, the concave static pressure oil reservoir plane is the plunger ball head protrusion, the edge of the throttle hole and the swash plate contact friction, the orifice oil is blocked can not overflow, the sliding shoe can not get oil lubrication, destructive metal friction occurs, and finally causes the above-mentioned plunger abnormal damage.

All in all, the production and manufacturing of piston pump parts is a high-precision work, and there are high requirements in terms of materials, heat treatment, and Hydraulic Pump working principle. Cheap price sometimes is not so good, it will cause a lot of trouble to the maintenance of the pump.

Buy with Super Hydraulics, get your peace of mind!

Contact: Frank Xie

Phone: +86-18951952293

Tel: +86-25-83408096

Email: sales@super-hyd.com

Add: 97#, Luxiying, Gulou Dis, Nanjing, China.

We chat