One of our customers complained that the A4VG180 charge pump used in a brand flatbed truck which was driven by an Original Rexroth A4VG180EP4D1 piston pump.

When the truck was working in a construction tunnel, the charge pump damaged 4 times within 2 months. The original charge pump came with the original Hydraulic Pump took nearly 2 months, and then three another brand new OEM charge pumps were replaced in a row, which were damaged after around ten days, ten hours, and even ten minutes. Unbelievable!!

Our repair service engineers arrived at the site and dismantled the weared three A4VG180 charge pumps that had been replaced. It was found that the cause of the damage was a broken gears and severe wear of the wear plate.

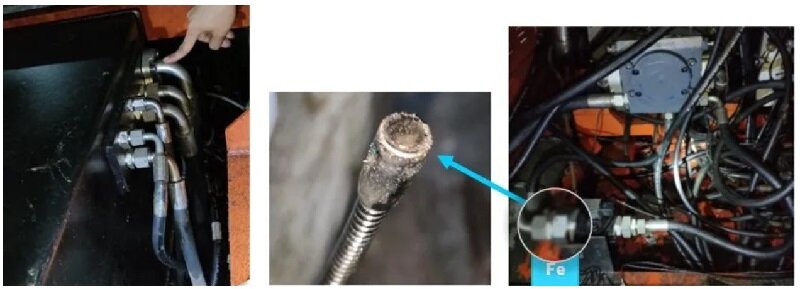

Step 1: Check the tank and pipelines:

After inspection, the oil tank and pipeline basically meet the hydraulic system requirements;

A large number of iron filings were found in the "Fe" outlet of the A4VG180 charge pump;

No iron filings were found in the main pump body.

The results of the on-site inspection show that the user has basically done a good job of cleaning the oil tank, replacing the new oil and filter element before replacing the oil replenishment pump each time, and only the oil replenishment pipeline is partially polluted, which does not affect the main pump. With the help of our repair service engineers, the user re-cleaned the contaminated lines on site.

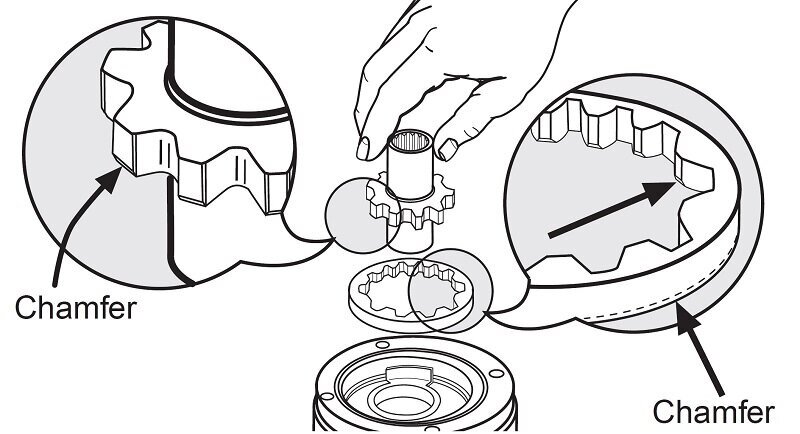

Step 2: Reinstall the charge pump

Immediately after that, we removed and inspected the 5th A4VG180 charge pump that was installed by the user but was not running, and reinstalled it. Here are a few things to keep an eye on, including:

A_The charge pump meshes the inside and outside directions of the gears;

B_Fixation of wear plates;

C_According to the rotation direction of the pump, determine the direction of suction and discharge;

D_When installing it on the main pump, pay attention to the tightening screw torque.

Step 3: Fill and vent the housing

A_While filling the oil tank, let the suction line exhaust until the hydraulic oil flows out from the suction port of the charge pump;

B_Open the "T" port on the upper part of the pump and fill the housing with clean hydraulic oil;

C_The tank level is increased to 80% of the tank height.

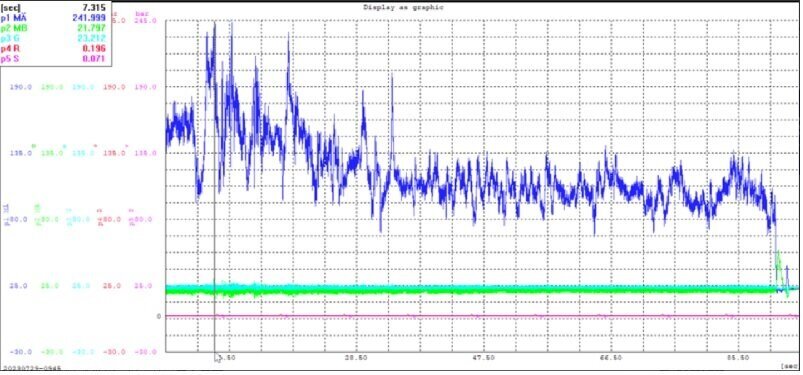

Step 4: Test under actual working conditions

Start the engine 2 times in a short period of time to fill the pump and lines with oil and lubrication. After idling for a period of time, start and walk uphill, gradually to large displacement, large throttle, and normal pressure. Downhill, low to high speed with normal pressure. After 2 days of testing, the pressure of the pump and the temperature of the pump housing are all normal.

With the help of Super Hydraulics after-sales service team, the multi-wheeled flatbed truck was finally able to resume smooth operation without any further failures of the charge pump damage.

Overall, the following are important to ensure the longevity of your charge pump:

1),Proper installation of charge pumps;

2),Hydraulic fluids that meet the cleanliness standards;

3),Exhaust of the suction line when the machine is stopped for the first time and after a long period of time is restarted;

4),Ensure that the suction pressure meets the requirements under the worst working conditions;

5),Correct commissioning process.

Contact: Frank Xie

Phone: +86-18951952293

Tel: +86-25-83408096

Email: sales@super-hyd.com

Add: 97#, Luxiying, Gulou Dis, Nanjing, China.

We chat