Have you ever experienced this type of Hydraulic Pump failure? During normal operation, there was a sudden noise of "da"~"da"~ "da"~a sudden noise in the machine. After that noise,the pump in the machine didn't run a long time and broken down shortly. The inside of the pump was a mess:-(

When this type of failure occurs, it can be cumbersome to deal with – not only does it involve replacing the pump with a new one, but it also involves filter replacement, oil line cleaning, oil tank cleaning, fluid replacement, and even cleaning and repairing other hydraulic components. If the measures taken during treatment are not comprehensive, it is also possible that the brand new pump replaced recently will be damaged again within a short period of time.

Some people of hydraulic industry attribute the cause of this kind of failure to the pump's suction air- "limited oil absorption". It sounds true. But is it true that all of these failures are caused by only suction air?

Hereby, let's take the hydraulic piston pump of Rexroth A10VSO100/31 series as an example, in the user manual, which states that "the suction pressure should not be lower than 0.8 bar absolute pressure, the housing oil drain pressure should not exceed 2 bar absolute pressure, and the housing oil drain pressure should not be higher than the suction pressure 0.5 bar".

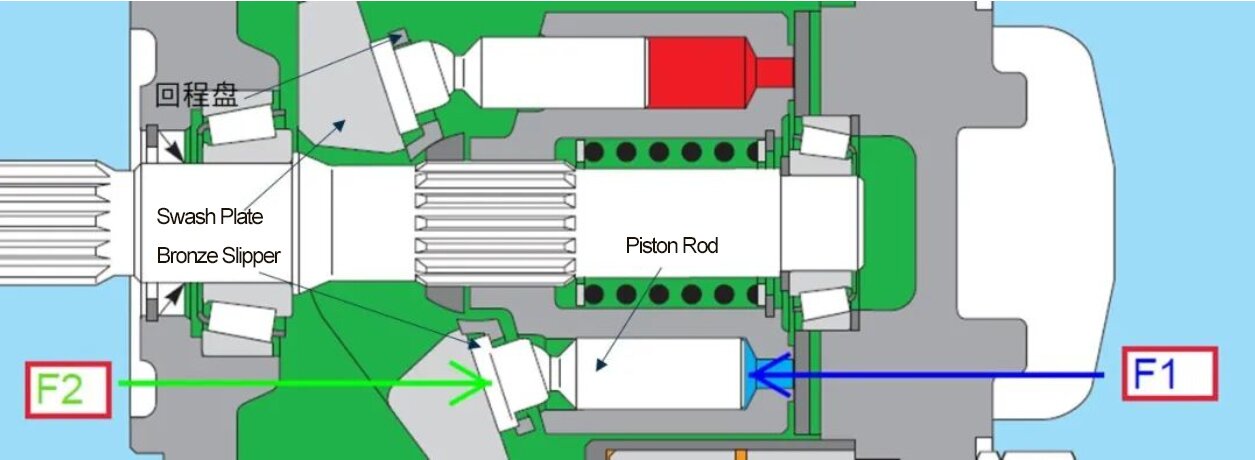

To interpret this data, we need to use the following structural diagram to simplify the analysis of the hydraulic force subjected to the pump piston shoes. Only by studying how the pump is broken can we find a solution to this problem.

F1: The force generated by oil absorption on the Piston Rod side; F2: Force generated by hydrostatic pressure on the side of the Bronze Slipper (related to the oil leakage of the housing)

F1 and F2 are able to keep the pison shoes balanced under normal conditions – the shoe is "conformed" to the swash plate thanks to the support of the oil film on the shoe and the action of the oil absorption on the piston rod. Think about it, what would happen if F1 and F2 were out of balance?

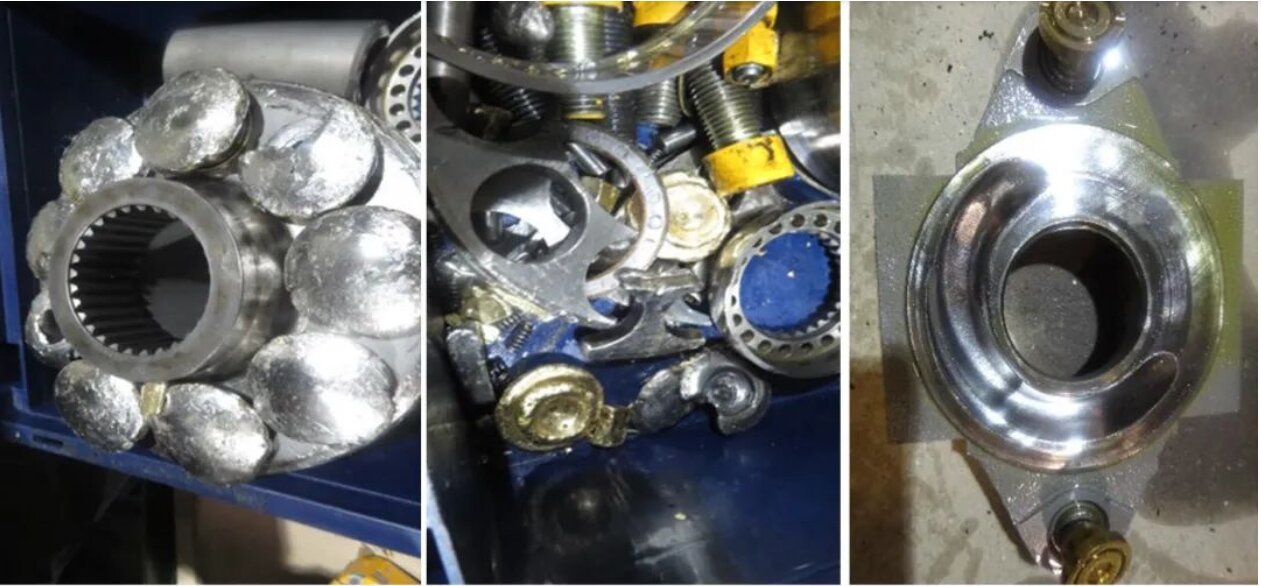

The piston rod in the suction zone is subjected to additional force and shifts to the suction side, and then the retainer plate is stressed and deformed. The edge of the shoe in contact with the retainer plate is deformed (flanged). Don't forget that the pump is rotating at a very high speed at this time, when the piston rod in this state is quickly transferred from the oil suction area to the oil pressure area, under the action of the pump working oil, the sliding shoe of this kind of piston will be "smashed" to the swash plate, resulting in the side (surface) of the sliding shoe in contact with the swash plate deformed (pounded) or even broken, and then the piston rod ball head will resist the swash plate, due to the relative rotation, the swash plate will be out of the "crescent" shaped pit like below picture.

At the same time, the retainer plate that is deformed in the suction zone is quickly released, and those that are deformed in the plastic range and those that exceed their strength will be fragmented. Some people use "air absorption" to define this kind of damage: such as poor oil absorption, oil absorption and filtration, inappropriate inner diameter of the oil suction pipeline, too long oil suction pipeline, too many elbows, too many reducers resulting in too much fluid resistance, etc., resulting in low oil suction pressure.

In fact, it is not comprehensive to define the causes of this type of failure by vacuuming. Evacuation causes these failures, but these failures are not necessarily caused by evacuation of these failures. Will the high leakage pressure of the housing cause this damage? The answer is yes. It should be emphasized that once the oil suction filter is blocked, it will bring the hidden danger of poor oil absorption.

Therefore, if you are confident in the processing, cleaning, and post-treatment of your oil tank and pipelines, and the configuration of oil pressure and return filters to effectively control the cleanliness of the system, please try not to use suction filters.

Contact: Frank Xie

Phone: +86-18951952293

Tel: +86-25-83408096

Email: sales@super-hyd.com

Add: 97#, Luxiying, Gulou Dis, Nanjing, China.

We chat