Did you know that in addition to the main inlet port, the hydraulic piston pumps also have a second auxiliary inlet?

That is, under certain conditions, the oil will change direction and flow in the opposite direction of the drain pipe of the piston pump housing.

Most of the friends who are engaged in hydraulics do not agree with this theory, Super Hydraulics' technical engineers have made a practical test on a domestic small excavator, and the measured data proves that the oil in the hydraulic piston pump housing can be sucked out, and the cylinder block, piston shoes and other moving friction pairs will be in a state of oil-free dry friction and a possible damage of the Hydraulic Pump.

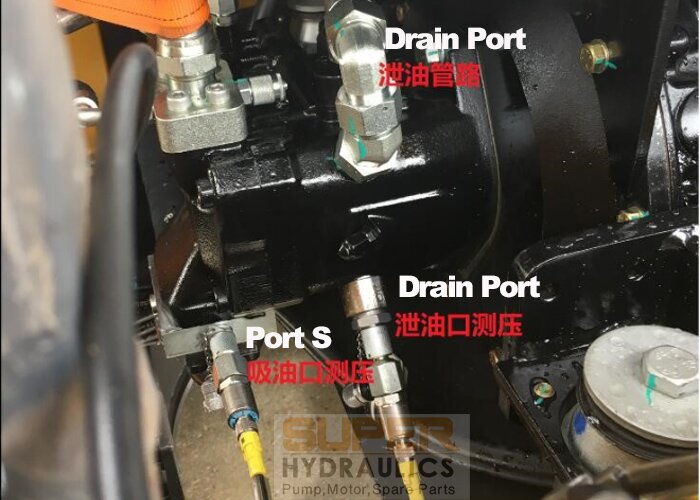

The tested domestic mini excavator uses a Rexroth A10VO76/52 series piston pump, and the engine speed is 2200rpm during the test. Three sensors are installed, one is installed on the inlet port(S port) of the pump (see picture 1), the other is installed on the case drain port, and the flowmeter is installed on the outlet port (P port) of the pump to detect the displacement.

Picture 1

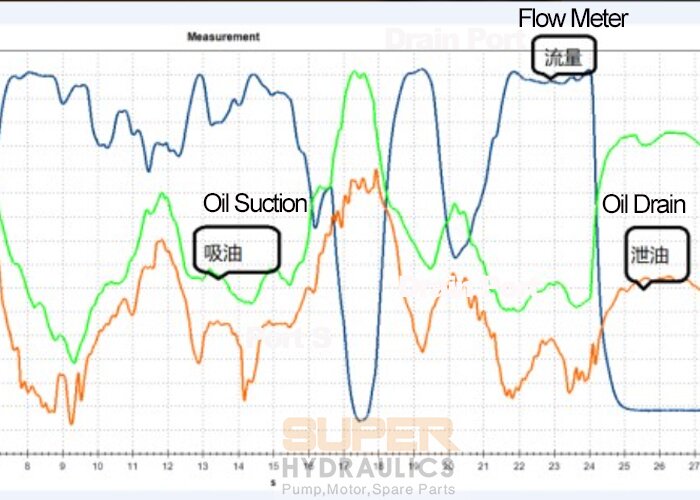

Picture 2

Picture two-color line and coordinate description:

---- Flow value curve, the curve detected by the flow meter

-----A pressure sensor mounted on the inlet port of the pump to detect the curve

-----Pressure sensor detection curve mounted on the flushing port of the pump casing

Description of the coordinate data on the surface:

The horizontal marker at the bottom of the diagram is a 30-second timeline from 0 on the left to the right.

The erection left line is the flow coordinates, which from 0 to the highest point are 170L.

The erection of the right line is the pressure coordinates, which are divided from the middle up and down, the 0 in the middle up to 0.08 bar is the positive pressure, and the 0 point in the middle of the figure is also the zero point of the altitude and the 0 point of the gauge pressure, which is the normal atmospheric pressure of our human breathing.

From the 0 point in the middle of the graph downwards is the vacuum, and the lower the point from the middle of the graph, the larger the value and the greater the vacuum.

Diagram description:

When the excavator is measured, the excavator needs to make an action, and the pressure and flow rate of the pump can change, but I don't know that this curve chart is the curve measured when doing that kind of action, so I can only roughly do an analysis from the curve chart.

From 0 seconds, the excavator has a movement, and the swash plate of the pump begins to change from the middle position to the minimum angle, so there is a decrease in the flow rate, the output flow rate of the pump decreases, the oil flow rate of the pipeline (S pipe) from the oil tank to the inlet port of the pump slows down, and the pressure in the S pipe begins to rise, from less than 0.01 bar in 0 seconds to 0.048 bar in 1 second, and the pressure in the pump casing also rises in this 1 second, from minus 0.01 bar to +0.02 bar.

Looking at these three curves from the vertical axis of the 3rd second, the oil drain of the pump has reached 160L/min, because it is a pump with a displacement of 76, which shows that when the speed of the pump reaches 2200 rpm, the swash plate of the pump has changed to the maximum angle (15°), and when the oil draind by the pump reaches 160L/min, the inlet port pressure of the pump on the same vertical shaft is from +0.048 bar to -0.03 bar (0.03 bar in vacuum: 0.973 bar absolute) and +0.023 bar to -0.07 bar (0.07 bar in vacuum) on the same vertical shaft.

From the 3rd to the 30th second, it becomes a common phenomenon: the amount of oil draind from the pump increases, the inlet port pressure decreases, and the housing pressure also decreases.

The oil drain of the pump increases, the pressure of the oil inlet port decreases, this regulation rate is easier to understand, that is to say: when the pump swash plate is at the maximum angle, the oil absorption increases, because the diameter of the S port pipe is small, it can not meet the pump's demand for oil, resulting in the increase of oil flow rate in the S pipe and the siphon phenomenon, the more serious the siphon phenomenon in the S pipe, the lower the pressure detected by the pressure sensor on the oil inlet port.

The pressure drop phenomenon of the pump casing is: when the pump is in the normal working state, the oil leaked by the three major friction pairs and the variable mechanism of the piston pump are leaked into the casing, when the oil volume in the casing reaches a saturated state, it will flow back to the oil tank through the casing drain pipe, when the oil inlet port of the pump produces a negative value of a certain value, the piston shoe of the pump is affected by the negative pressure gravitational force of the S pipeline when inleting oil, and the fir force on the piston shoe rod also acts on the sliding shoe, causing the sliding shoe to take off the plate. The oil in the pump casing flows backwards into the cylinder bore from the center hole of the sliding shoe oil storage chamber and the center hole of the piston shoe rod, and the oil in the casing is sucked away, and the pipeline that communicates between the oil drain port of the casing and the oil tank fails to replenish the oil in time, which causes the vacuum degree in the pump casing.

Under the normal state of the piston pump, the leakage oil generated by the three major friction pairs and variable mechanisms of the piston pump will flow to the oil tank through the casing oil drain pipeline, and the oil of the casing will not be regurgitated.

Condition 1: The head pressure of the oil outlet of the oil tank is low, the inner diameter of the S pipeline is thin, the S pipeline is long or has a sharp bend, and there is a docking step in the S pipeline to form a liquid resistance and consume energy.

Condition 2: The flow rate in the liquid S pipeline is fast (the correct flow rate is <0.5 m/s), and the maximum oil absorption capacity of the moment when the pump swash plate variable changes from the minimum angle to the maximum angle.

Condition 3, the piston pump has a high number of revolutions, the pump has a large oil drain volume, and the output pressure of the pump P port is less than 25bar.

The lack of oil in the piston shoe pump casing is a serious hazard to the pump, such as the light burning plate, burning bearing, dry friction sliding shoe, and the heavy three major friction pair burning, which seriously endangers the life of the piston pump.

Picture 3

Picture 3 explaination:

This is a pump parts damage photo of a Rexroth A10VO63/52 series piston pump, and there is also a lack of oil in the housing, this pump was only used for three days and then failed, and the swash plate rubbed against the piston shoe appeared to wear and tear, the upper part of the swash plate 180 degrees is the oil pressure area of the piston shoe, because the piston shoe is in the oil pressure state and produces a hydrostatic oil film, and no contact friction is formed between the piston shoe and the swash plate, so the upper area of the swash plate on the picture is a bright belt.

When the piston shoe is transferred to the oil absorption zone, the piston rod siphons in the cylinder bore and causes the oil-free dry friction between the piston shoe and the swash plate, and the contact friction between the piston shoe and the swash plate makes the themself wear out.

1. The correct design and installation method of the pipeline connected to the drain oil of the piston pump casing and the oil tank is as follows: the inner diameter of the pipeline should be greater than 1.5 times the diameter of the drain port of the housing, so as to ensure that the flow rate of the second inlet port of the pump reaches 15% of the first inlet port of the pump.

2. The oil drain port pipeline should be connected to the oil tank wall 200mm below the oil level without any oil resistance, so as to promote the housing to keep the oil at all times.

Super Hydraulics, 25 years of Experience in Hydraulic Pumps, Motors, and spare parts! Your reliable hydraulic partner in China!

Contact: Frank Xie

Phone: +86-18915959615

Tel: +86-18915959615

Email: sales@super-hyd.com

Add: 97#, Luxiying, Gulou Dis, Nanjing, China.

We chat